Your cart is currently empty!

Tag: Belt

-

How to Size Your Belt

Held belts are designed to fit you just right, at the middle notch. It is easy to order the wrong size, that’s why this video makes it easy to get the ideal fit.

You can triangulate your size with dressmakers tape, a correct pant size, and an existing belt. If you only have one of those three, you can still wager a good guess.

Refer to Your Pants

If you have absolutely no way to measure, observe your pant size and match it or round up one inch.

If the pant size is an odd number, round up one inch. In this video, the pants are loose from age, even though my waist is larger than the size on the tag. I know, it’s weird.

If the pants fit quite nicely at an even number, that is the belt you want, and it is probably your measurement too.

Women’s pants do not correlate to waist size, so this point applies mostly to men’s wear.

Fit an Existing Belt

For this method, you can use any belt that notches up tight on your waist. After that, you need a yard stick or measuring tape.

The distance between the buckle’s prong and the notch that fits you is approximately your waist size.

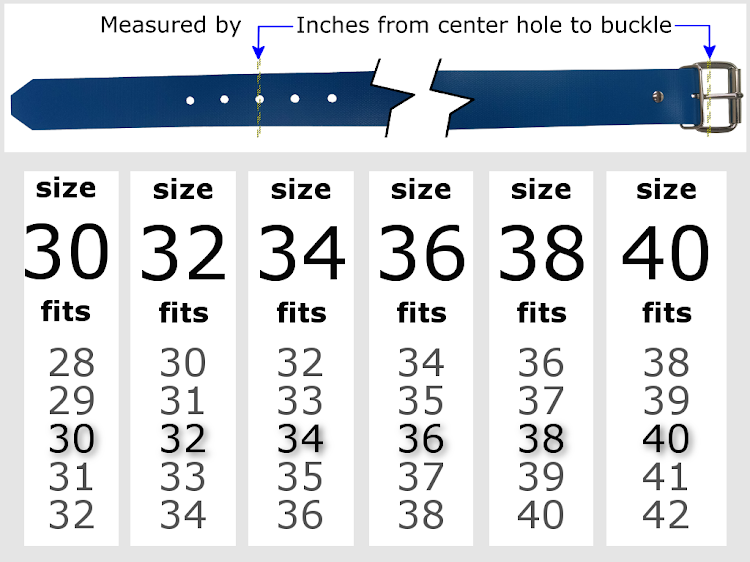

Official Held Belt Sizing Chart Measure Your Waist

This is the absolute best way to measure for the right belt, but it does require dressmakers tape.

See the video to understand where to measure. It is important to measure at the hip bone, as this is where pants and belts traditionally rest.

You can substitute dressmakers tape with rope or string. Simply mark the point on the string that meets back up to your hip after wrapping around, then measure that with a yard stick or measuring tape.

Ordering The Right Size

If you have all three of these numbers, then you are surely ready to put in your next Held belt order.

The tightest notch on your belt should be equal to or one inch smaller than the actual measurement of your waist.

Standard issue designs are made in small batches to keep an inventory ranging between sizes 28 and 38, accommodating waists from 26 to 40 inches.

Custom tailored orders are always available, just contact the shop directly.

-

How to Change Your Buckle

Standard Held belt designs feature a single or dual snap set that allows for the free exchange of buckles.

Once you have removed the buckle and you are reinserting it, it can be a little confusing. This video offers pointers within the demonstration to help avoid mistakes.

For example, the ring keeper must go in first, this piece holds the strap down after it is notched.

A center bar buckle extends in a full circle and self-contains the strap, eliminating the need for a keeper ring.

Not all buckle types are interchangeable. Especially flat panel buckles require a different type of design with smaller notches.

Look for additional buckles available in the shop as an add-on at checkout.

-

How to Maintain Your Held Belt

Offering some tips about maintaining your “classic” Held belt.

This is by far the best selling design in the catalogue and these steps apply broadly across other models. The “classic” has the attractive appearance of a standard black leather belt, but it is actually waterproof vulcanized rubber, making it the perfect belt for workers.

The belt in this video has been exposed to all kinds of labor, from dish rooms to construction sites, for four years. It has taken on paint, oils, extra weight as a tool belt, and it has years to go before coming out of service.

Proper cleaning, oiling, and clipping extends the life and appearance of the belt against all of the abuse it goes through.

Removing Paint and Cleaning

The rubber strap accepts paint but it is removable. Using standard mineral spirit paint thinner and a microfiber cloth, it can be rubbed out by hand.

If your belt does not have paint stains, any oil and grease that the strap is exposed to can be removed with dish soap and water.

Although it can take water, make sure to quickly dry the belt and wipe off all remaining dust and debris.

Oiling the Strap

Rubber is not unlike leather, its microscopic fibers will dry out and lose integrity. It turns out that non-silicone based leather oil is beneficial, although silicone and rubber go hand in hand, it is not ideal for a wearable product.

Huberd’s brand shoe leather oil is a natural legacy product from a small company based in Colorado. The product was created in nineteenth century Oregon, and was a solution for timber manufacturing waste at the time and remains so today.

Common olive oil is a known classic moisturizer for wearable rubbers like rain boots. It is an option that most people have on hand.

Clipping Frayed Edges

This step applies to almost every Held strap.

They are super strong, but nothing is impervious to wear. Depending on how hard you work your belt, it wears gradually at the edges.

The edges can be clipped routinely. For best results, obtain 5.5 inch angled scissors. These are good to keep with your sewing kit anyway.

By bending the backside of the belt toward you, it makes targeting the frayed sections much easier, while the angled scissor gives you a more ergonomic experience.

Reinforcing the Notches

We offer reinforcement grommets. A good tool belt will include these type of brass grommets, as belt notches always expand faster under extra weight.

The belt in this video had grommets added after more than three years of use, when the used notches began to lose their integrity.

Grommets are very difficult to press into Held’s dense straps without a 2-ton press like the kind used in the shop. That is why we offer mail-order service. Refer to the repair and customize section of this website.